Product Description

BMW Tuneable Hybrid Urethane Engine Mounts - Powerflex PFF5-4650

BMW Tuneable Hybrid Urethane Engine Mounts - Powerflex PFF5-4650

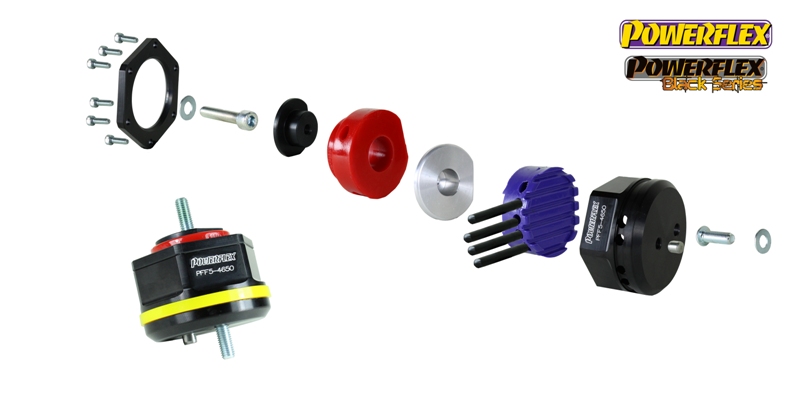

Why have only one engine mount? The Powerflex Tuneable "Hybrid" Urethane & Aluminum engine mounts for the E36, E46, and E90/E92 M3 are configurable to match your current car spec. It's "tuneable" to multiple performance settings -

- Street Performance with a dual-urethane core (65A and 80A bushings)

- Track Performance using stiffening pins inserted into the mount. The mount does not need to be removed to insert the pins, making this a tuneable mount from the paddock.

Also available is a full-race mount with a 95A black urethane core and stiffening pins. With the stiffest configuration the Powerlfex mount is a whopping 675% stiffer than a new M3 engine mount!

Other BMW urethane engine mounts are made with a single solid urethane block of one durometer. This is simple and cheap to manufacture but is not ideal for most scenarios - the mount is either too stiff or not stiff enough and poor manufactuing quality leads to continued problems. Powerflex properly engineered their mount to absorb vibrations while providing exceptional strength and sheer resistance. The design uses a "soft" Red 65A urethane to absorb Noise, Vibration, and Harshness (NVH) with a stiffer Purple 80A urethane for improved strength and performance. If you desire a stiffer mount for tracking or drifting the mount can be made stiffer without removing it from the car! Unsnap the yellow retaining collar and insert the four stiffening rods. This reduces deflection in the mount and makes it stronger.

| This parts fits the following models. |

|---|

Powerflex has extensive knowledge and design experience in automotive suspension and chassis systems. These design skills have been combined with advanced polyurethane manufacturing techniques leading to the development of a wide range of high-performance automotive polyurethane components that are second to none in quality and performance. All component manufacturing is carried out by our in-house engineers utilizing the latest automatic processing equipment to ensure premium quality. Testing of new components is carried out both on test rigs and on the actual vehicle the parts are designed for. Stainless steel and aluminum components are also machined in-house on the latest computer-controlled equipment to ensure perfect repeatability and exceptional quality. The special type of polyurethane used by Powerflex is an advanced proprietary material which has unique properties. This ensures that each product not only offers the high-performance capabilities our customers expect, but also the exceptionally long life and quality they demand - without increased vibration or noise.