Product Description

BMW N54/N55 Helix HPFP Overdrive Unit - Spool Performance SP-54HX-1

BMW N54/N55 Helix HPFP Overdrive Unit - Spool Performance SP-54HX-1

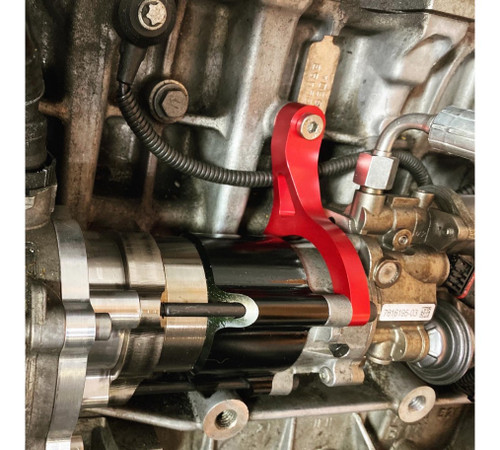

Spool Performance Helix HPFP overdrive system

Spool Performance is really excited to introduce our latest product offering to the N54/early N55 community, the Helix overdrive unit. We have been testing this for almost a year now and here it is finally!!

What is the Helix?

The Helix is simply put, a planetary gearbox for your High-pressure fuel pump. It is very similar to what you would find in your automatic transmission. A planetary gearbox allows you to change gear ratios in an axial configuration. It consists of three types of gears- ring gear, planet gears, and a sun gear. In our configuration, the planet gears and the sun gears are on different rotating axles and the ring gear is stationary. The particular configuration of the gears and their spatial fixturing allows an axial increase in shaft speed from the input to the output of the unit.

Why do you need it

The N54/early n55 high-pressure pump is a very capable and over-engineered piece of hardware. They do a good job supplying fuel at high pressures at stock power levels. As we start tuning and pushing more power, we start seeing drops in the high pressure. What is happening here is that the high-pressure pump is not able pump as much fuel as the injectors are injecting into the cylinders and hence causing the rail pressures to drop. The pump at this point is running out of displacement volume. With a rotary pump like the continental HPFP, an easier way to increase displacement is to spin the pump faster which results in an increased number of delivery strokes per cycle. The Helix helps you do exactly this and thus helps overcome a big limitation in N54/early N55 fuel systems without the complexity of a secondary port injection system.

Fueling limits with the Helix

We have differentiated our current overdrives into two for different end-user scenarios. The Helix will support up to 600whp worth of flow on full e85 and 750+ on e60 mixes. The Helix Xtreme will support 750whp worth of flow on full e85 and 850+ on an e60 mix or other gasoline blends. Helix is currently ready for launch and the Helix Xtreme is still in longevity testing.

Concerns on HPFP Longevity

It is no secret that the continental Hpfps have been subject to failures and recalls in the past. So we made it a high priority during testing to study the modes on failure and the effects of overdriving the pump on the failure modes. From investigating a number of failed units, two modes of failure were established as the most common. The first mode is inlet metering valve actuation failure due to failures in actuation solenoid coil and second is the limp home mode bypass valve leaking. The limp home mode valve connects the low-pressure inlet to the high-pressure outlet of the pump and remains closed as long as there is a higher pressure on the high-pressure side. It is designed to flow in the case of an hpfp failure. On older units, this valve starts leaking from high pressure to the low-pressure side preventing the hpfp from being able to build full pressure in the rails. The valve relies on rubber elements to seal under normal operation and we infer that prolonged use of E85 affecting the rubber is the main culprit behind this mode of failure. We did find cracked bellows as well but we estimate it to be very rare since only one out of more than 20 failed pumps were affected by this. We also analyzed the oil out of high mileage units and they showed very little metal content and physical examination of the squash plate, the springs and pistons proved that these elements are designed to last and had very little wear. In short, most failure modes on the hpfp unit are modes that are not affected by over spinning the pump in any way.

Tune changes

Tune changes are required to use the Helix system to its full potential. The changes are available with all major tuners and Spool performance will provide the necessary calibration changes needed for the same upon request.

Our goal at SPOOL PERFORMANCE is to offer the highest quality parts for the most affordable price without sacrificing performance. We pride ourselves on our commitment to exceeding the industry standard for customer service, performance, and product quality. Before the release of any of our products, our engineers at SPOOL PERFORMANCE make sure that our products will live up to expectations. The development of any part goes through stages of rigorous research, CAD designing, prototype development, CFD analysis, and endurance testing. Fitment, functionality, and longevity are extensively tested before any product makes it to our website for sales. During our beta testing stage, testers from all across the nation and often around the world will push our products to the limit to make sure that our products exceed customer expectations in different environmental settings and across a variety of different power levels our customers are at.

SPOOL PERFORMANCE was built on a foundation of integrity and this is why we take such pride in our products. But we don’t stop at offering products that are superior in quality. We try our best at SPOOL PERFORMANCE to match our products' high level of performance and quality when it comes to customer service. Our customer service team is always on standby to answer any questions or concerns about the product and its application. We understand no matter how many hours of testing and engineering goes into a product; issues can still come up. But as our customer, you can be rest assured that If any problem was to arise with SPOOL PERFORMANCE products we will be there by your side to look into the cause of the issue and work with you to the best of our ability to resolve it.