Product Description

BMW G1 Intercooled Supercharger Kit - ESS S65-G1-FULL-KIT

BMW G1 Intercooled Supercharger Kit - ESS S65-G1-FULL-KIT

Kit Features:

- ESS Engineering G1 supercharger unit

- Cast aluminum ESS intake manifold with integrated 6061 T6 velocity stacks optimized for boost

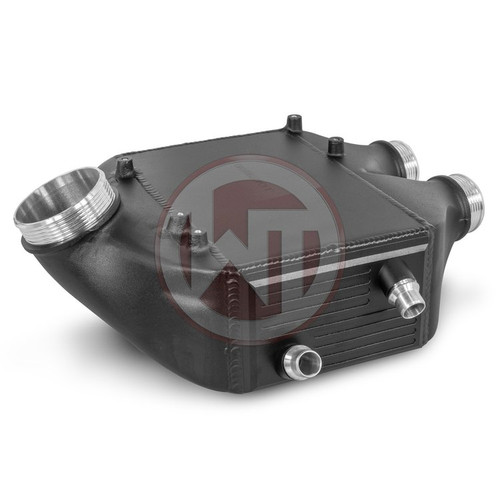

- High capacity liquid intercooler system

- Vortech Maxflow Race bypass assembly

- High temperature cast plastic intake system for SC

- Uni-belt drive system with additional ESS lifetime billet idlers

- Heavy-Duty drive belt

- CNC hard anodized brackets and hardware

- High temperature silicone hoses with clamps

- ESS oil breather assembly designed for boost

- 8 larger Bosch Motorsport fuel injectors, G1 spec

- 6PK S65/98mm (91AKI/95RON) and 6PK S65/94mm (93AKI/98RON) supercharger pulleys

- K&N high flow air filter

- ESS E-Flash reprogramming and diagnostic interface

- Perfectly optimized, dyno tweaked MSS60 ECU software with removed top speed governor, calibrated for G1 spec injectors

- Detailed, step-by-step installation manual

- All installation hardware included

- 2 year/unlimited mileage warranty

Specs:

- Boost pressure: 6.5-7.5 PSI Intercooled

- Horsepower: 150-180whp (45-55%) gain over stock depending on fuel quality and pulley used

- Torque: 30-40% gain over stock depending on fuel quality and pulley used

- Application intended for: E90 M3, E92 M3, E93 M3 from 2008-2013

S65 G1 Intercooled Supercharger System: Intercooled, 6.5-7.5PSI system compatible with manual and DCT. 91AKI/95RON or above required. *HFC or cat-delete mid section recommended for optimal results.

ESS Tuning was founded in Aremark, Norway in 1995, providing supercharger solutions to the mighty BMW platform. Since then, we’ve amassed a legendary reputation as the largest BMW supercharger system manufacturer in the world, and as a well-known innovator in the chip and tuning sector with our extensive expertise in Bosch and Siemens engine control systems. Our products undergo the strictest production standards and unmatched testing, all part of our goal to achieve uncompromised performance. First, we dial in our tune and run our computerized load dyno tests beyond anything feasible of even the most spirited driving. After which, our development cars are put through a grueling 50,000 mile test involving time on the track, high speed autobahn driving, extreme heat and cold, as well as your normal everyday commute. We ensure that only OEM grade components and materials are used in everything we make. Finally, fit and finish is key, making sure that everything comes together underneath the hood, no fabrication required. In addition, all extra power made from our kits is delivered in a smooth and balanced manner, just as the factory would have intended. Simply put, we don’t release our products until it passes our rigorous standards.