About BE Bearings

![]()

Background:

- BMW M5 (2005-2010), BMW M3 (2008-2013) can suffer early bearing failure due to inadequate rod bearing clearance.

- Insufficient clearance means insufficient oil flow, excessive bearing surface heat, and premature wear.

- These symptoms can lead to early bearing failure and a very expensive engine rebuild.

- Problem can be addressed during engine rebuild, but it's expensive.

- Some people switched to thinner oils -- as a stopgap measure.

- Other stopgap measures include anti-friction teflon coated factory bearings, WPC anti-friction treated factory bearings, and custom bearings with same clearance as stock.

- "Coated" factory bearings decreased clearance. This is not a good idea.

- WPC treated bearings slightly increase clearance, but are a stopgap.

- Custom bearings keeping factory clearance doesn't fix the problem, but allows you to track lead and copper in Blackstone oil analysis.

- Newer factory bearings (2010.5 and later) are made from tin-aluminum, not lead-copper. Tin-aluminum bearings are 4-times harder on the surface than lead-copper bearings. This extra hardness shows signs of doing more damage to motors as there seems to be more bearing failures with 2010.5 and later vehicles. Tin-aluminum bearings also don't show the same signs of premature wear in Blackstone oil analysis due to lack of lead and copper.

- A better solution was needed.

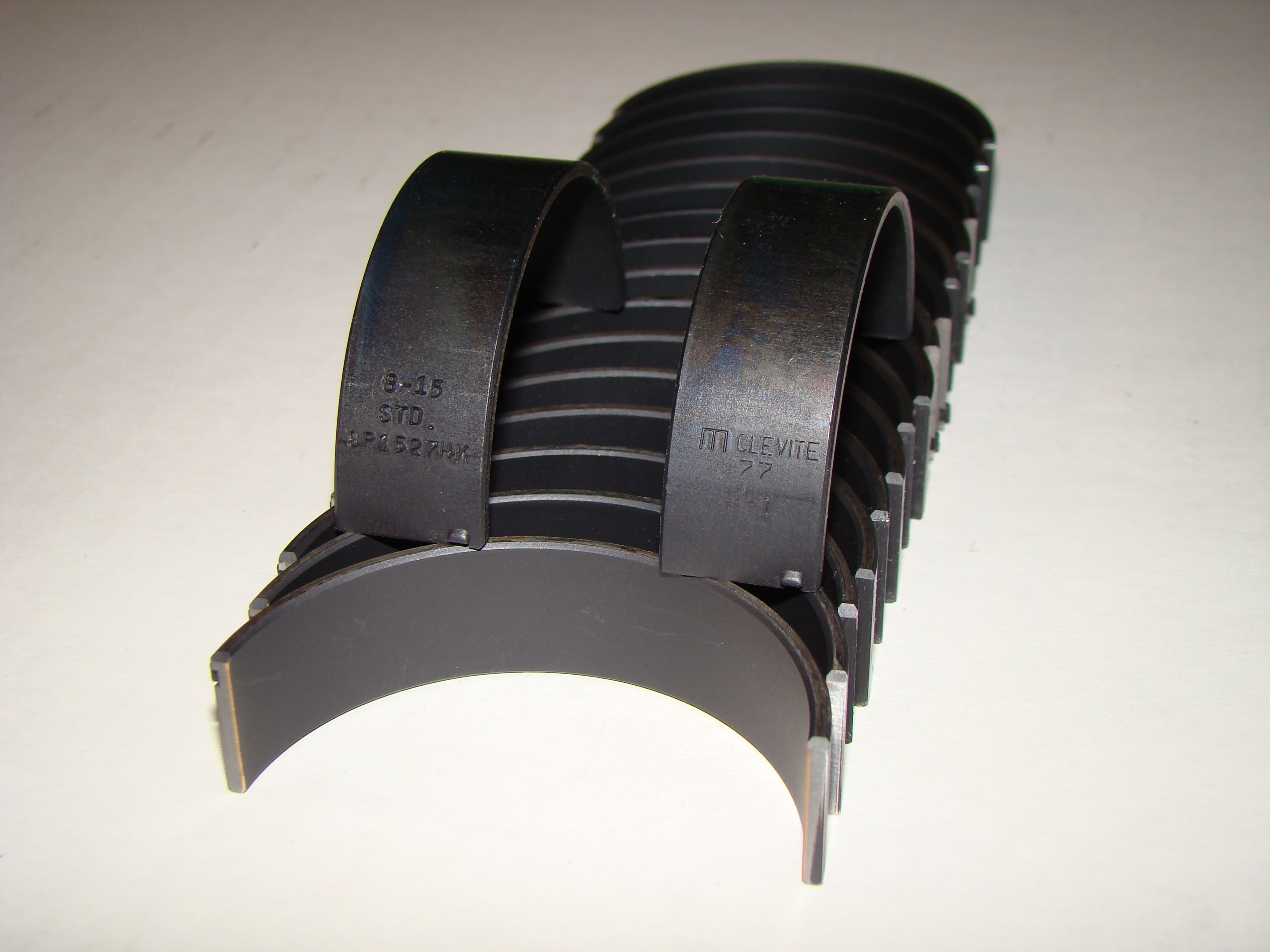

Better Design

- Designed to address and fix the rod bearing clearance issue.

- Designed for use with factory 10W60 weight oils.

- Increases oil flow.

- Improves lubrication for "Start-Stop" vehicles over factory bearings.

- Designed in consultation with leading industry experts from NASCAR, Indy Car, and former BMW M-Division engine designer.

- Designed and manufactured by Clevite, factory BMW bearing supplier.

- Traditional lead-copper bearing design; less wear on crankshaft journals, traceable with Blackstone oil analysis.

- Each bearing is measured and size-binned. Allows for custom bearing selection when necessary.